Zero Halogen Low Smoke PVC Compounds

Zero Halogen Low Smoke PVC Compounds Specification

- Material

- Soft Pvc

- HS Code

- 3904

- Type

- Zero Halogen Low Smoke PVC Compounds

- Color

- Any Color

- Shape

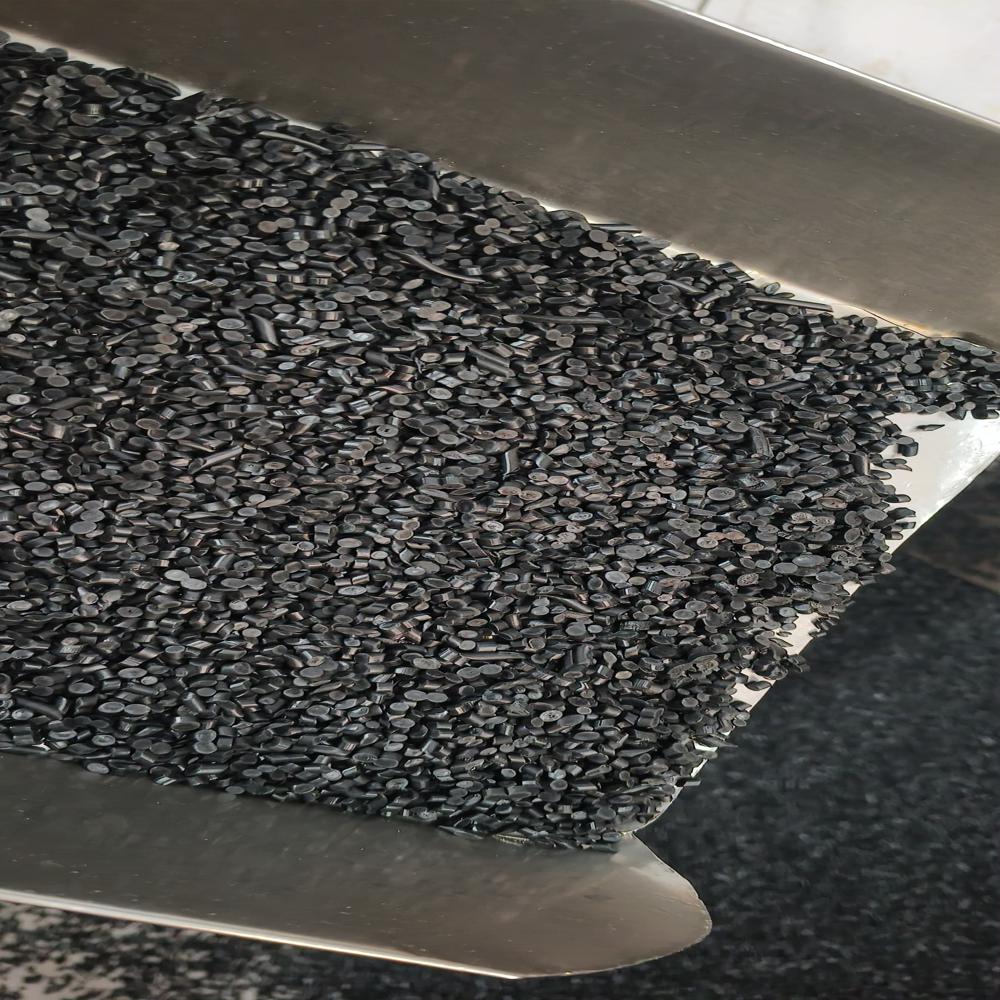

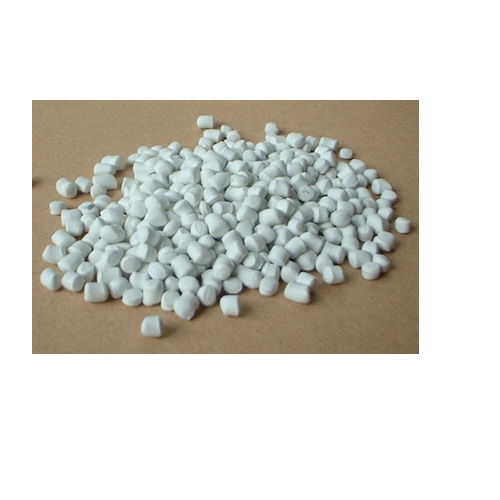

- Granules

- Relative Density

- 1.60 Gram per cubic centimeter(g/cm3)

Zero Halogen Low Smoke PVC Compounds Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Domestic Market

- All India

About Zero Halogen Low Smoke PVC Compounds

A low smoke zero halogen polyurethane jacket is the characteristic of the material behaviour. The cables are flame retardant and self-extinguishing in the event of a fire, showing low smoke emissions and are100% halogen free.

| Form | GRANULES |

| Color | ALL |

| Size | SMALL |

| Material | PVC |

| Packaging Type | 25 KG BAG |

| Usage/ Application | COLOURING OF PVC COMPOUNDS |

Exceptional Safety and Low Smoke Emission

Our zero halogen low smoke PVC granules are developed to minimize the release of toxic halogens and smoke, ensuring greater safety during fire incidents. These characteristics make them ideal for applications in public buildings, transportation, and critical infrastructure, where maintaining clear visibility and reducing hazardous emissions are essential.

Versatile Applications and Customization

Engineered from soft PVC, our compounds are adaptable to a range of manufacturing processes and can be produced in any color to match customer requirements. Their granule form ensures easy processing and uniformity, making them well-suited for cables, wiring, and insulation used across industries.

FAQs of Zero Halogen Low Smoke PVC Compounds:

Q: How are zero halogen low smoke PVC granules manufactured?

A: These granules are produced using high-quality soft PVC with specific additives to eliminate halogens and suppress smoke generation during combustion. The manufacturing process involves compounding, extrusion, and pelletization to achieve a uniform and easy-to-handle granule form.Q: What are the key benefits of using zero halogen low smoke PVC compounds?

A: The primary benefits include reduced toxicity and smoke emission during fires, improved safety for occupants and equipment, and compliance with fire safety regulations. They also offer excellent flexibility and color customization without compromising material performance.Q: Where are these compounds commonly used?

A: Zero halogen low smoke PVC compounds are widely used in the manufacturing of cables, wire insulation, and sheathing for buildings, transportation systems, data centers, and other environments where fire safety and low toxicity are critical.Q: When should you choose zero halogen low smoke compounds over standard PVC?

A: These compounds are ideal when installation environments require minimized health hazards during fires, such as hospitals, schools, public transport, and densely populated areas, or when regulatory standards mandate enhanced safety measures.Q: What is the usage process for these granules in cable production?

A: Manufacturers process the granules through standard extrusion or molding techniques, applying them as sheathing or insulation layers around conductive components in cables. Their uniformity supports efficient production and consistent final product quality.Q: How does the relative density of 1.60 g/cm3 affect product performance?

A: A relative density of 1.60 g/cm3 provides a balanced combination of mechanical strength and flexibility, making these compounds suitable for a range of demanding applications without compromising ease of handling or processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Compounds Category

ST 1 Pvc Compound

Price 30 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Shape : Granules

Material : PVC

Color : Any Color

PVC Compounds Manufacturer

Price 75.0 INR / Ton

Minimum Order Quantity : 2 Kilograms

Shape : Granules

Material : PVC

Type : Polymer

Reprocessed PVC Compound

Price 30 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Shape : Granules

Material : Soft Pvc

Type : Other, Reprocessed PVC Compound

Color : Any Color

FR/FRLS Compounds

Price 100 INR / Kilograms

Minimum Order Quantity : 1000KG Kilograms

Shape : Granules

Material : PVC

Type : Other, FR/FRLS Compounds

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS